The Duravant family of operating companies serve the food processing, packaging and material handling segments.

nVenia is a Packaging Equipment Manufacturer Supplying Integrated Primary, Secondary and End-of-Line Packaging Solutions Focused on Quality, Durability and Innovation

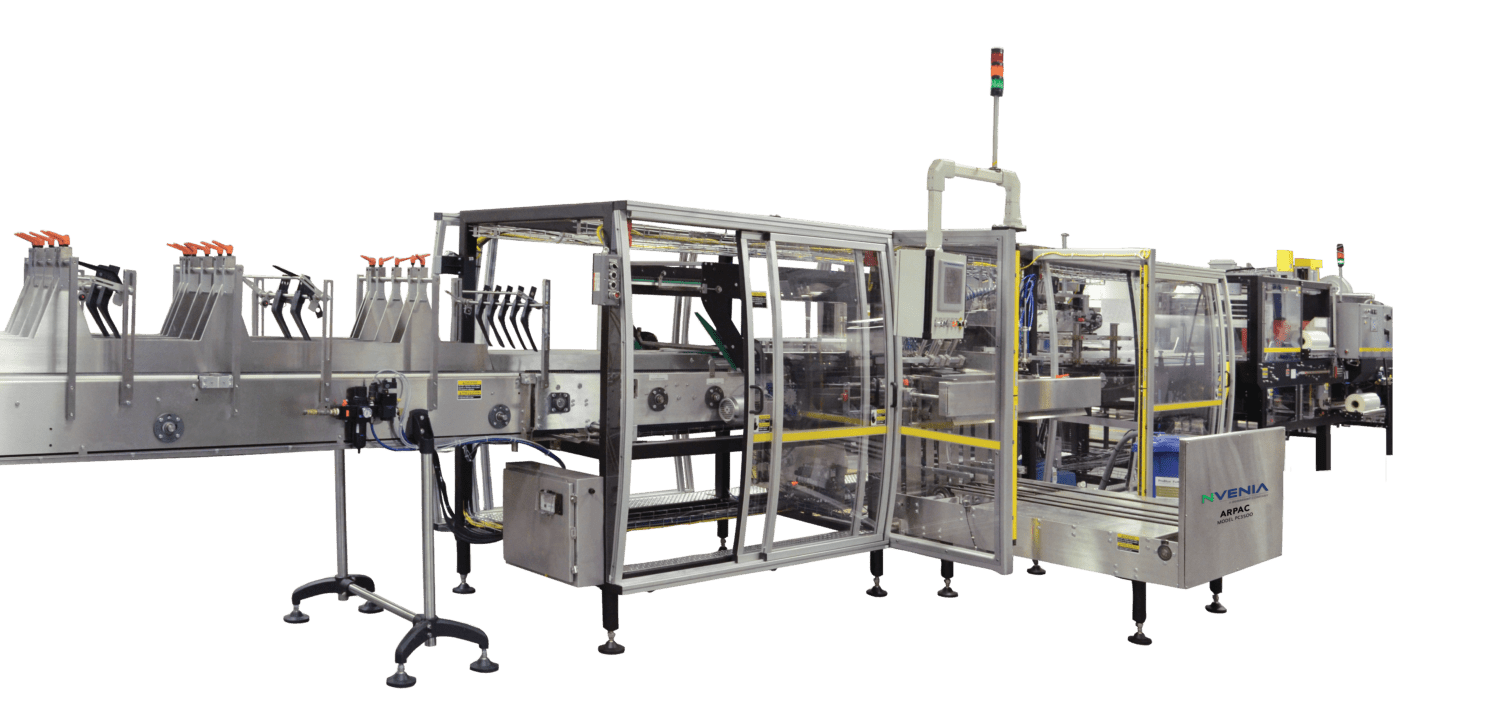

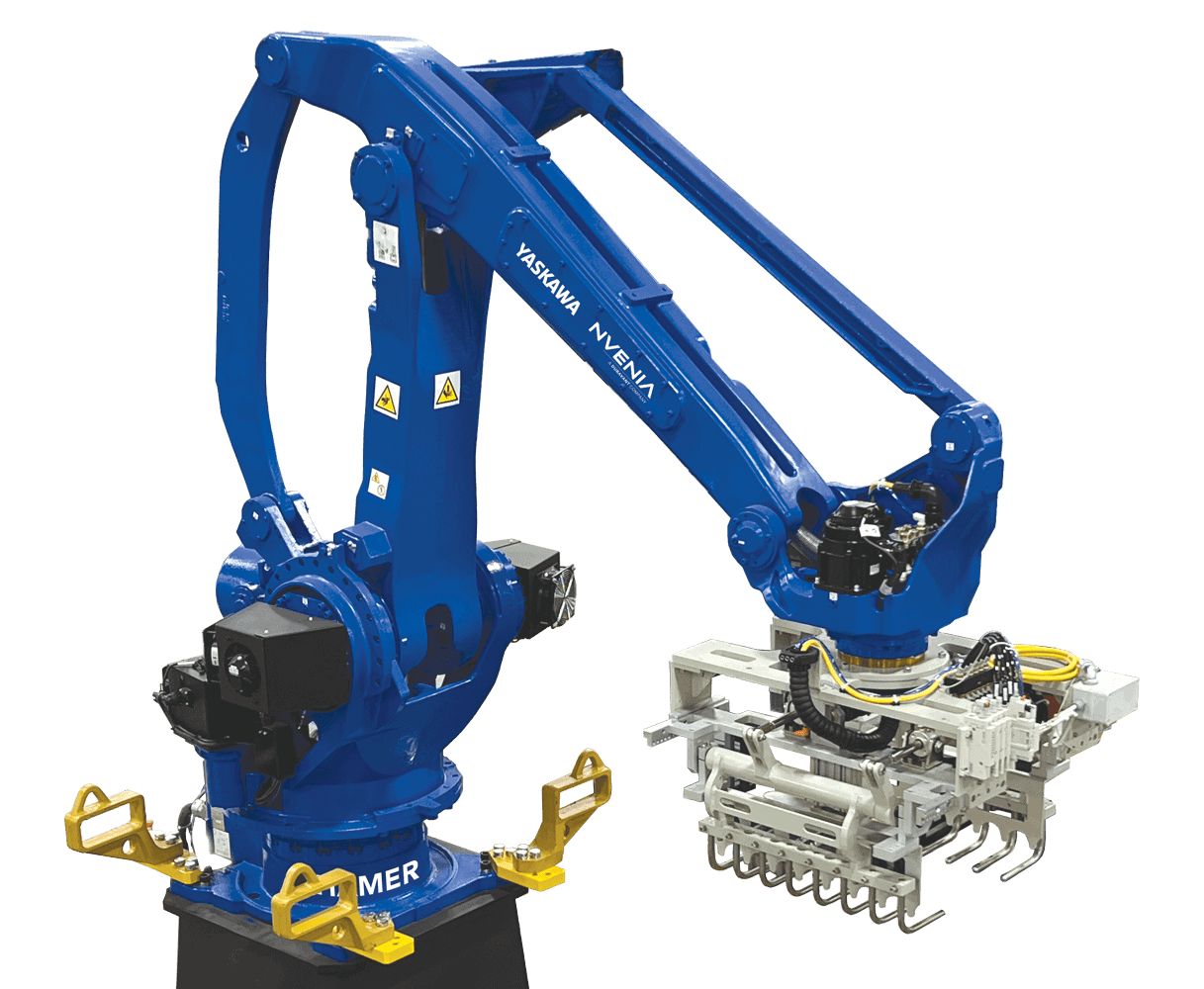

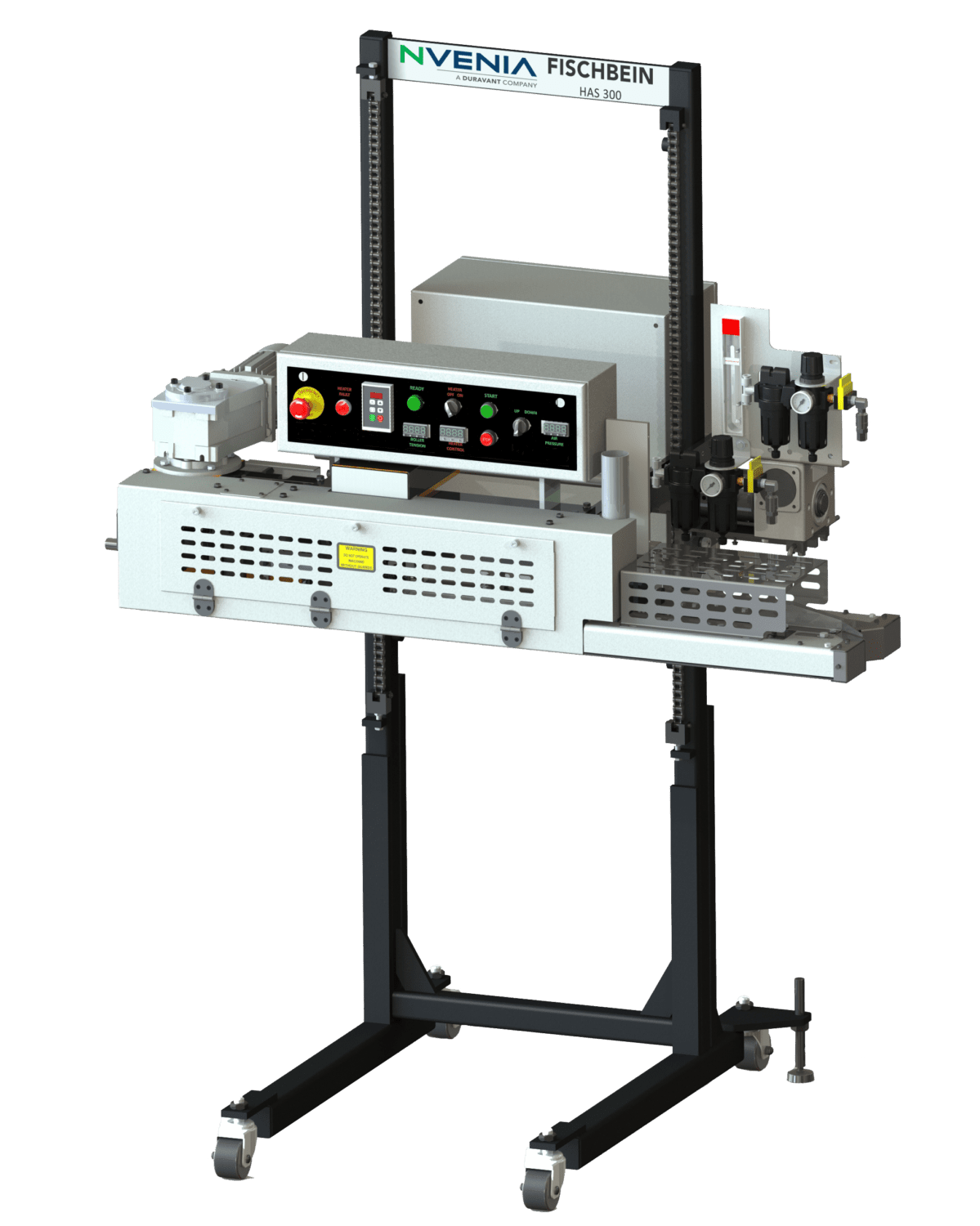

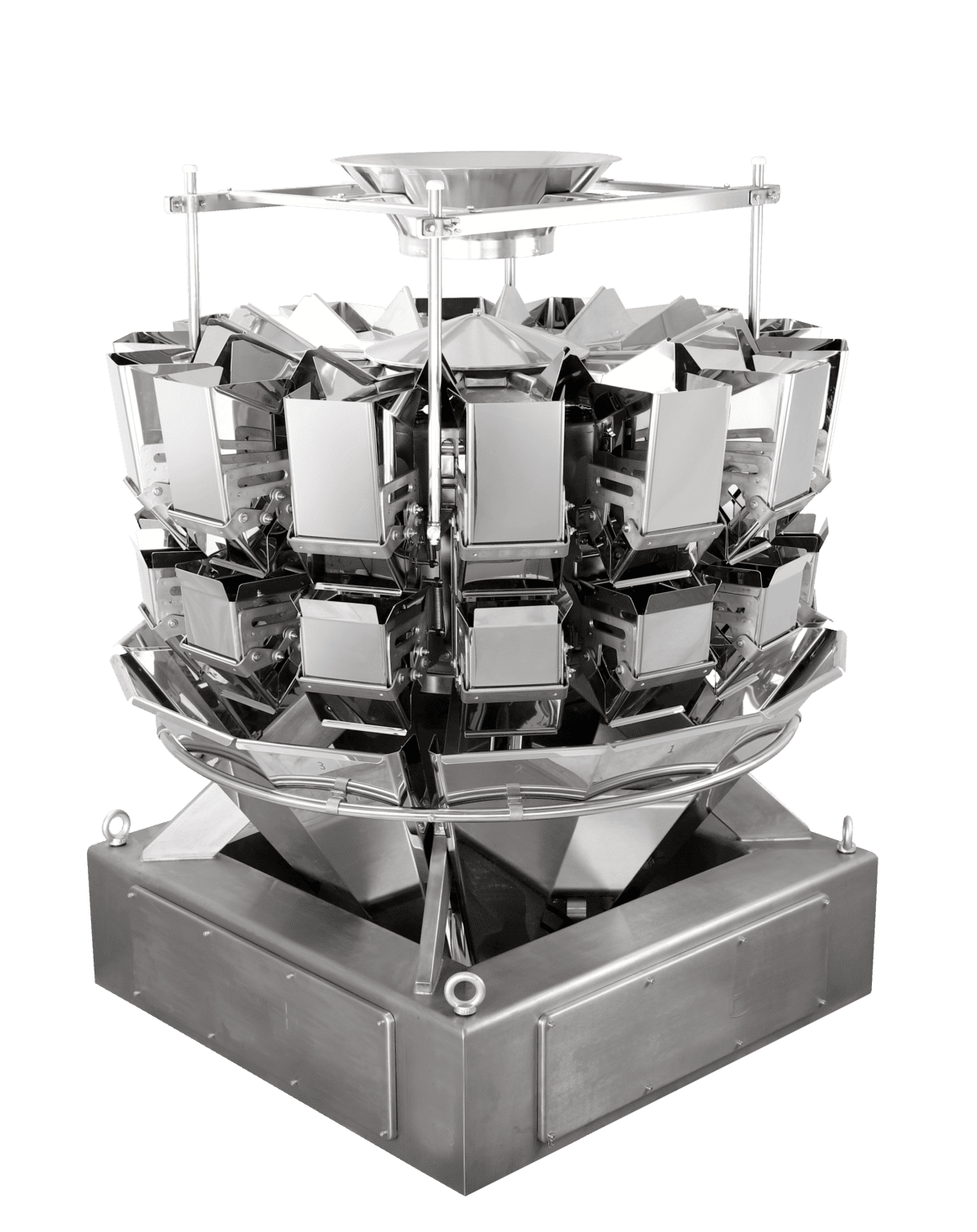

nVenia brings Duravant packaging leaders Arpac, Hamer-Fischbein, and Ohlson Packaging together to create next-level packaging equipment integration and innovation. One name, in one location, with one shared focus: our customers and the problems they need to solve.

As your packaging machine suppliers, we can provide a wide range of primary, secondary, and end-of-line packaging systems thanks to our many capabilities. Our expertise as packing machine manufacturers includes conceptualizing, designing, manufacturing, installing, and integrating, and servicing this equipment.

To learn more about what makes us a leader among primary and secondary packaging companies, get in touch with us today or request a quote.

Featured Products

Our primary, secondary, and end-of-line packaging machinery can be found in the CPG, food, and industrial sectors. Practically any type of operation looking to automate its processes, increase production, and reduce labor costs can benefit from choosing nVenia as their packaging automation partner.

Packaging Solutions for Multiple Applications

SupportPro

SupportPro delivers a total equipment lifecycle management program that optimizes the performance of your equipment.

Latest News & Updates

Discontinuation of ARPAC Brand Fully Automatic Stretch Wrappers

nVenia ARPAC Brand 1085SS Model High Speed Food Slicer Discontinuation & Transition – Update

Upcoming Events

Pet Food Forum

Pack Expo International