The Duravant family of operating companies serve the food processing, packaging and material handling segments.

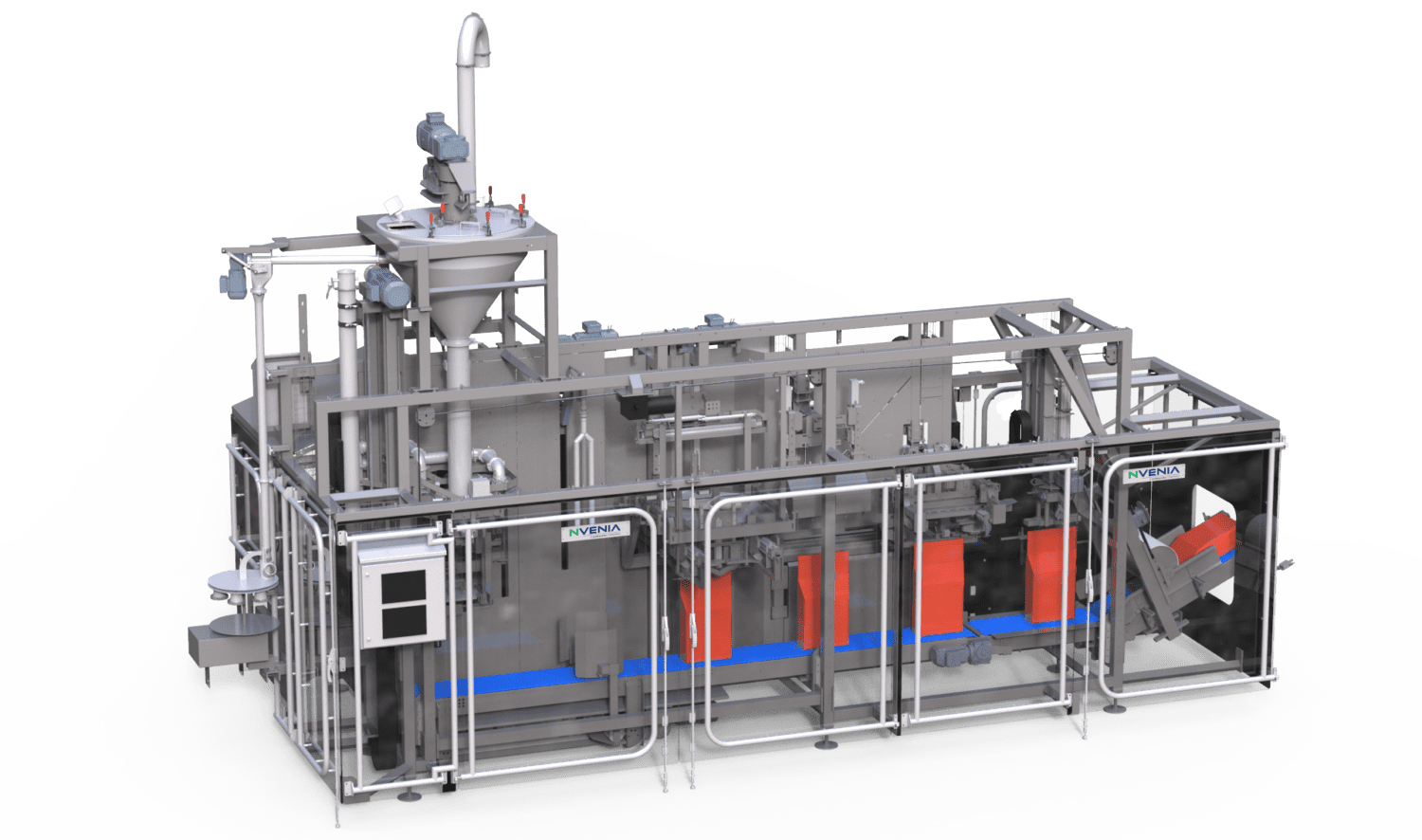

Open Mouth Bagging Machines

Leaders in Open Mouth Bagging Equipment

nVenia’s HAMER Brand of open-mouth bagging solutions continues to expand due to their rugged reliability and performance in the most demanding production environments where pre-made open mouth bags are desired.

Their broad versatility allows many types of products to be bagged, such as animal feed, food, agricultural seed, minerals and chemicals. Our equipment is compatible with the most popular types of open-mouth bags including poly, poly-woven laminate, paper, paper/poly lined, pillow side gusset, or pinch style, and can deliver continual, regular performance.

Are you interested in this product?

We are here to help.