The Duravant family of operating companies serve the food processing, packaging and material handling segments.

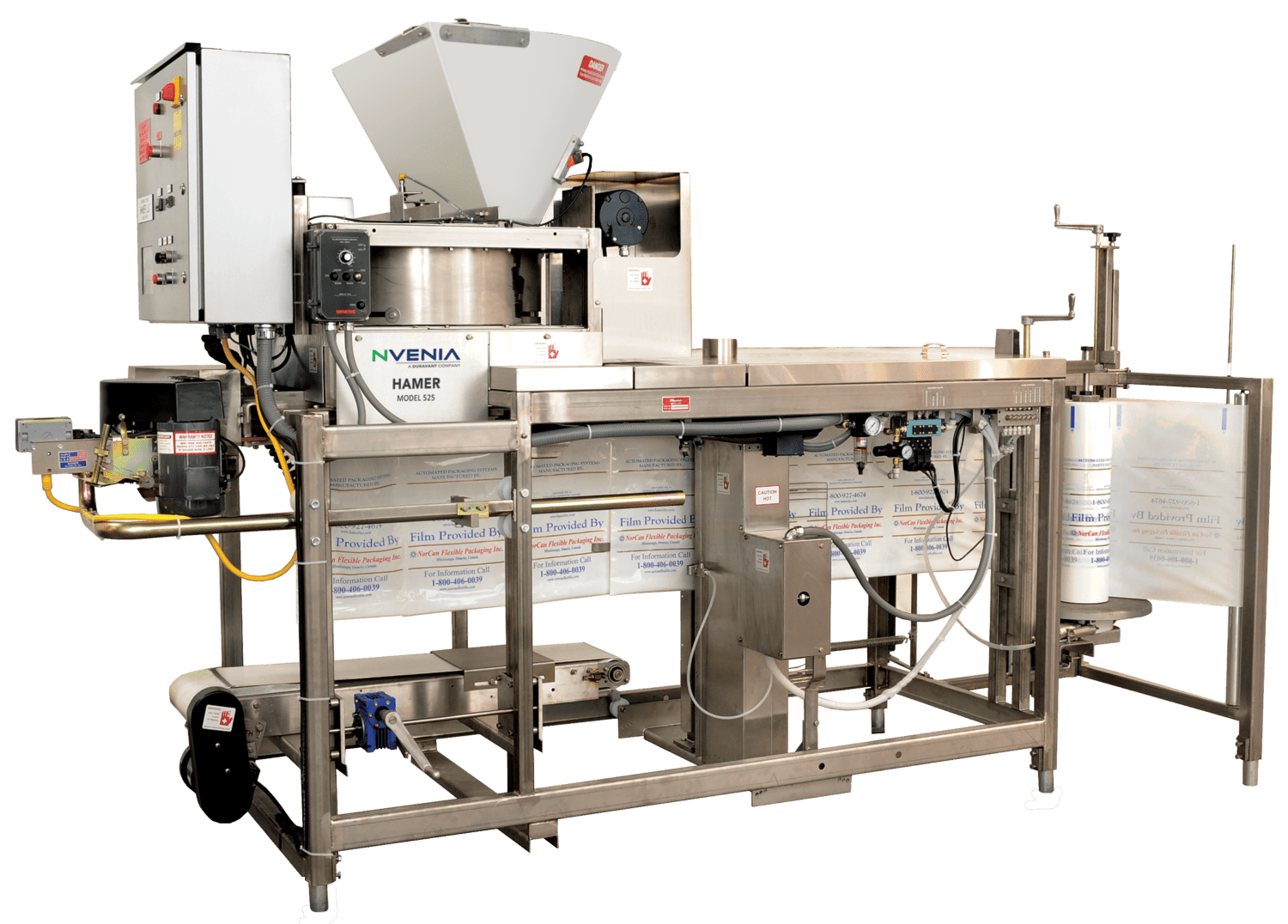

Bagging and Palletizing Machines for Packaged Ice

Ice Packaging Automation Equipment

nVenia has been engineering and manufacturing industrial ice equipment and offering innovative, low-cost ice packing machine solutions under our HAMER Brand for nearly 70 years.

We offer multiple form, fill, & seal automated machines designed specifically for packaging ice, and palletizing systems to manage output. Production volume is key to ice plant automation, especially during busy summer months and holidays. With high bagging rates, our equipment ensures you will always have the product on hand during peak demand.

Modern Ice Equipment and Supply is our premier full-service provider for all your ice packaging automation equipment. Modern Ice and nVenia have been partners in the industry for over 50 years. Modern Ice delivers value-added services including equipment training, technical service and consultation, installation, layout and design services and turn-key engineering solutions.

Are you interested in this product?

We are here to help.