The Duravant family of operating companies serve the food processing, packaging and material handling segments.

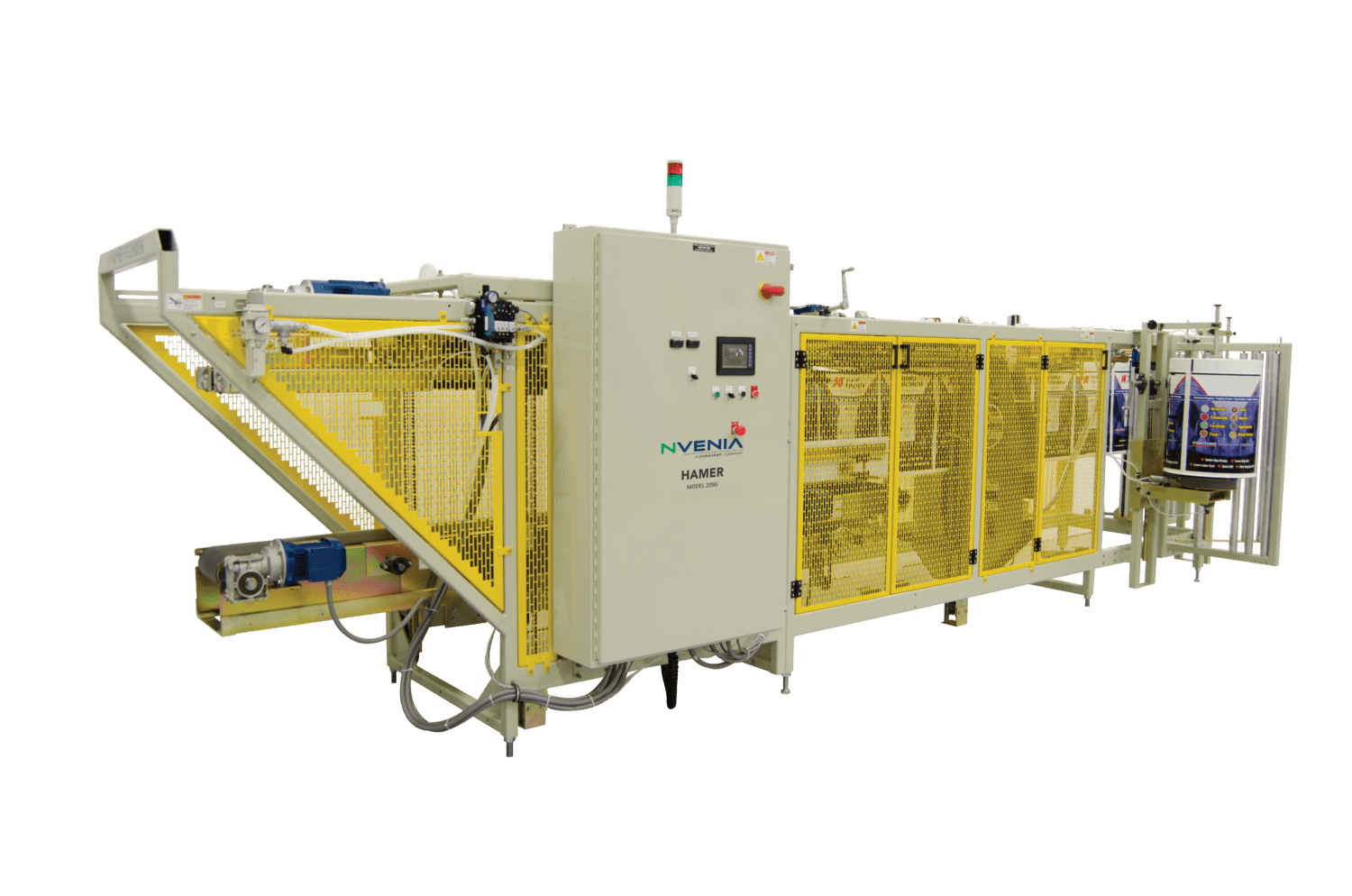

Hamer Brand Model 3100 Form Fill & Seal (FFS) Bagging Machine

Our Hamer Model 3100 Form, Fill & Seal is designed for extreme duty automated bagging. It is built specifically for the most difficult products in demanding environments. Ideal for mining, minerals, corrosives and aggregates packaging, the Model 3100 offers longevity and high speed. It can be utilized as a stand-alone packaging machine or integrated into a fully automated packaging line.

Our Hamer Model 3100 features a sturdy 6″ structural steel frame, 1/2″ structural steel zinc dichromate plated subassemblies, plated steel pulleys with sealed bearings, and B series belts. All operational components are top-mounted for simplicity and all adjustment controls are scaled for simple, trouble-free bag size changes. A pneumatically actuated bag perforator provides up to twelve vertical holes along the edge of the bag to facilitate air removal for effective bag palletizing. The perforators are mounted to the hot knife assembly, improving performance and reducing wear, and Teflon knife backing keeps bag seams clean.

Are you interested in this product?

We are here to help.

Features

- 24 VDC Solid State Controls

- UL listed control panels

- Simplified operator touch panel

- Heavy-duty powder coated 6 in structural steel frame

- 304 stainless steel product contact points

- Zinc dichromate plated internal components

- Heavy-duty hardened self-cleaning dual sealed pulleys

- Heavy-duty self cleaning conveyors with UHMW lined bag guides

- Expanded metal operator safety gates with cut-offs

- JamControl(TM) bag jam sensor for overfilled bag detection and removal

- EasyChange(TM) jaw sizes for fast bag size changes

- MaxFill II(TM) chute provides maximum product volume and faster filling

- Bag counting, operational alarms, and diagnostics

- QuikAdjustTM chute adjustment for fast bag size change

- Variable speed AC motors on heat sealer

- Double heat seal top seal with knurl for seal integrity

- Extended length bag top seal cooling plenum

Standard Specs

Standard Specs

Machine Dimensions

60″ H x 60″ W x 240″ L

Speed

Up to 30 BPM

Film Types

Bag Sizes:

- Width: 9″ to 22″, Length: up to 33″

- Bag Thickness: 2 mil to 8 mil low density polyethylene

Polyethylene Film Stock Specifications:

- Film type: C-fold rollstock

- Material thickness: 2 mil to 8 mil

- Core diameter: 3″ on 24 in O.D. vertical roll

- Roll diameter: 24″ vertical or up to 40″ on “B” version

- Optional gusset: 3″ to 6″, 4 mil max

Electrical Requirements

230 VAC, 3 PH, 60 Hz, 60 A Standard

Other power options available

Air Requirements

45 CFM @ 80 PSI

Accessories

Accessories

OPTIONS:

- Multiple product infeed and transition chutes with MaxFill(TM) for faster bag filling

- Hardox (R) 1/8″ steel chutes and transitions also available

- Transition chute shaker

- Additional fill opening assembly (additional chutes sold separately)

- Bag top seal air scrubber for dust removal

- Vertical film lift device

- Mitered corner sealer (45 degree bag corners)

- Bag top trimmer with film scrap removal (additional air required)

- Reinforced bag handle with bag header

- EZ Load II(TM) horizontal roll holder

- Power film lift with powder coated frame, operator control panel, and splice assist

- Horizontal film roll stock holder with powder coated frame and powered film pull

- Horizontal film roll stock holder with mounting and controls for Bellmark Printer (printer not included)

- 460 V, 3 PH power

- 460 V, 3 PH power with NEMA 4X 304 stainless steel enclosure for corrosive environments

- Allen Bradley Compactlogix PLC upgrade

- Inkjet printer

- Thermal transfer printers in multiple sizes

- NEMA 4X stainless steel transformer for 460V, 3PH, 60 Hz

- NEMA 4X corrosion resistant control panel with junction boxes in 304 stainless steel

- Corrosion protection package with painted conveyor belts and heat sealer and 304 stainless steel hardware

- Quick disconnects for easy machine movement

- Steel wheel kit for rail mounting