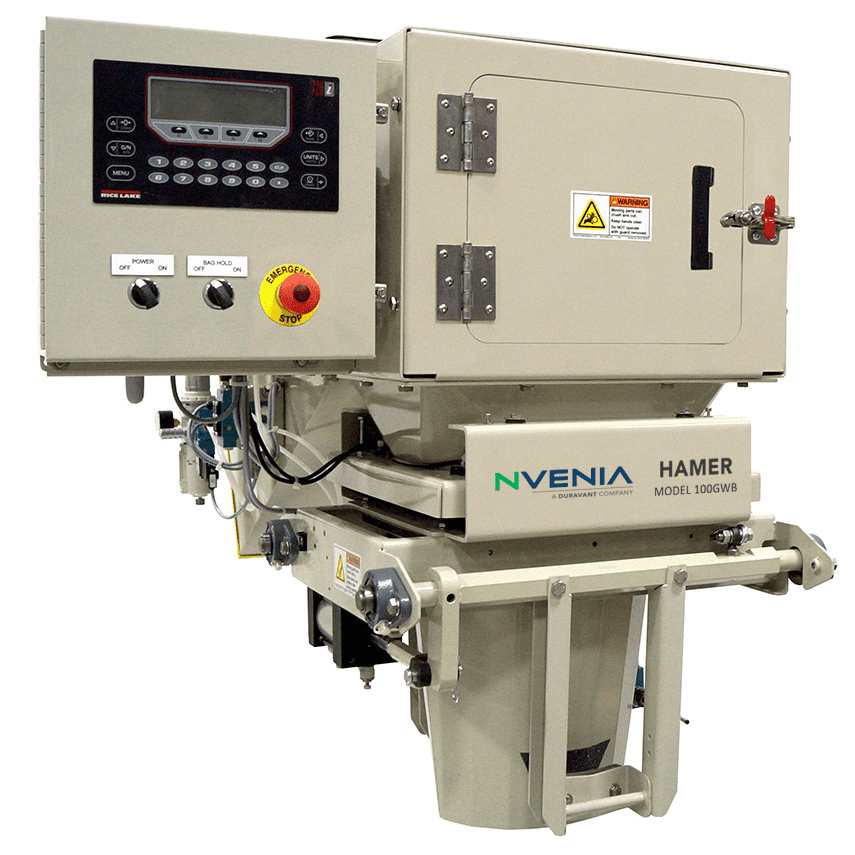

The Duravant family of operating companies serve the food processing, packaging and material handling segments.

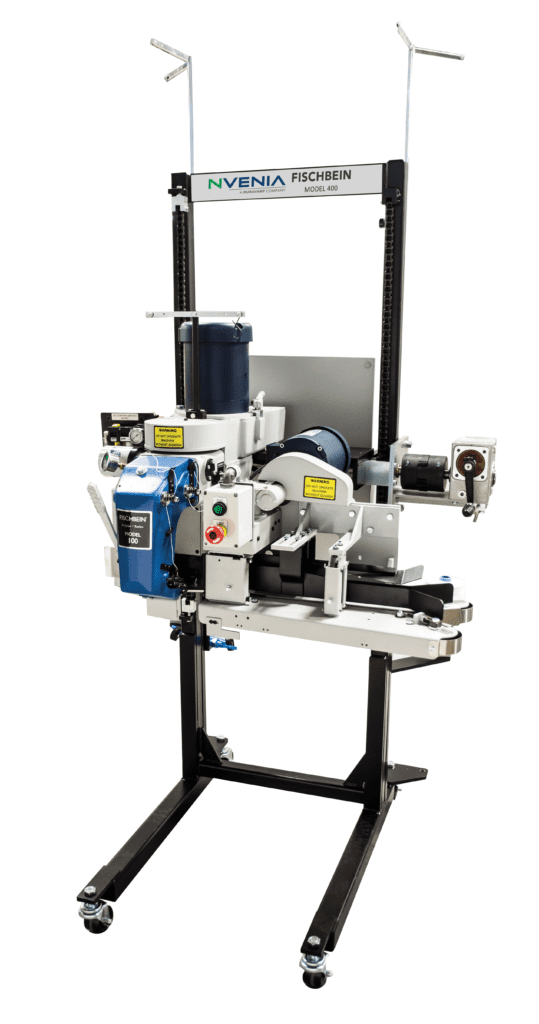

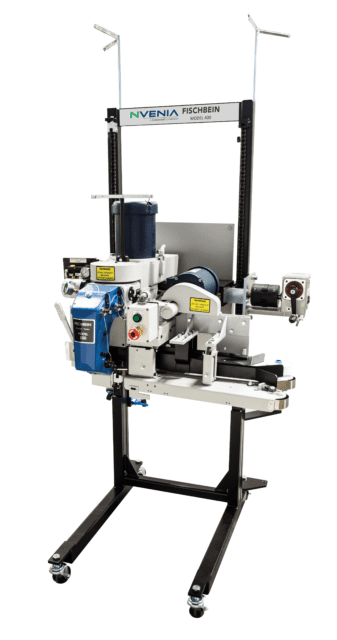

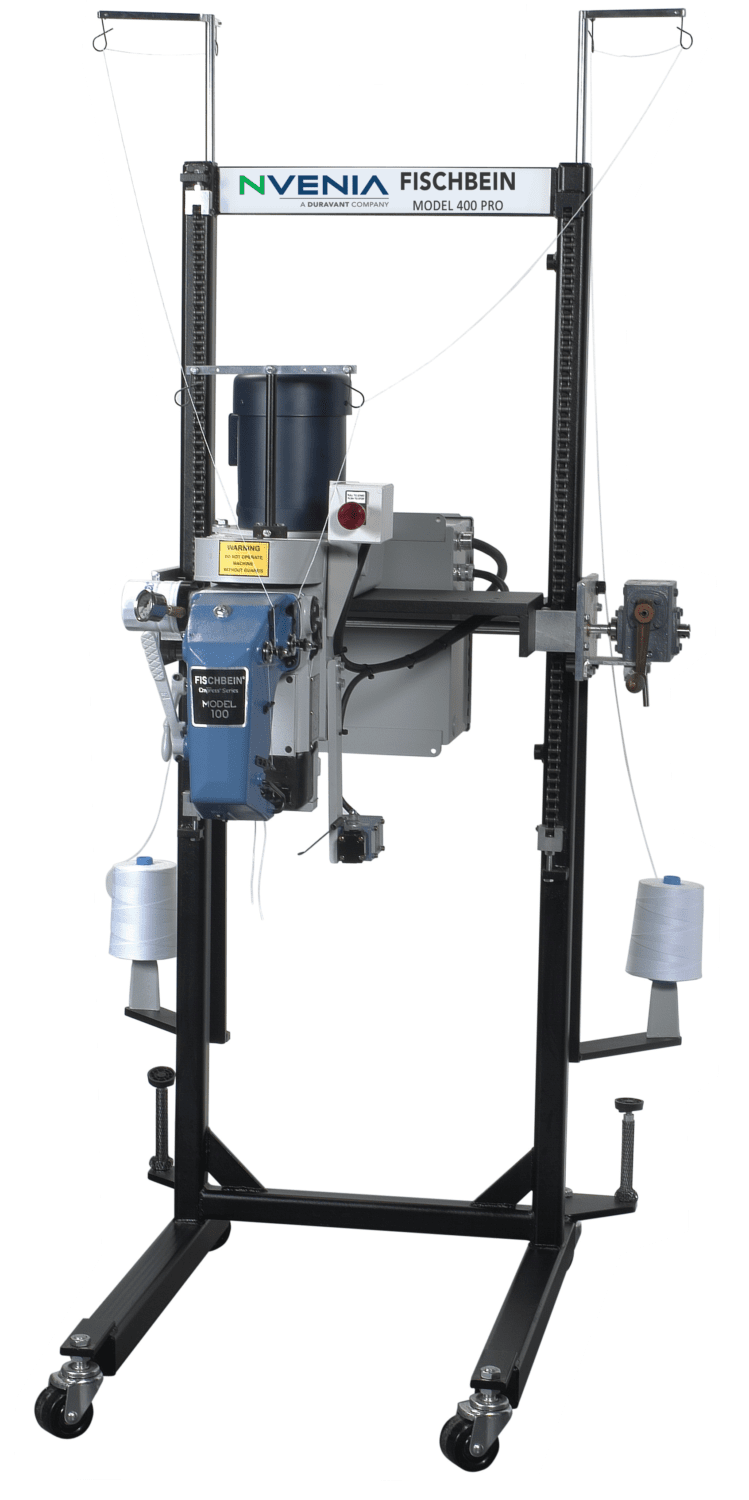

Fischbein Brand Plain Sew System – Model 400 NS

The Fischbein Brand 400 NS sets the industry standard for quality and cost-effective bag sewing. Operating at adjustable speeds up to 55 linear feet per minute, the Model 400 NS is safe, easy to use, and easily integrated into any manual or semi-automated bagging line. The automated infeed system automatically guides the top of the bag through the entire bag sewing process. The 400 NS features an air thread pusher which directs the thread into the system’s cutting knife.

Are you interested in this product?

We are here to help.

Features

- Closes a variety of pillow style or gusseted bags, including multi-wall paper, laminated and non-laminated woven polypropylene, and jute.

- Fast. Safe. Automated. The leading edge of the bag is fed into the infeed, which automatically guides the bag’s top through the entire bag sewing process.

- With its self-lubricating system, the Empress 100 delivers trouble-free, smooth performance with low vibration. Operating speed is adjustable from 35 to 55 linear feet per minute.

- Solenoid operated air thread pusher automatically directs the thread into the system’s cutting knife, without operator assistance.

- Exclusive sewing-head swing feature makes threading the 400 NS™ a snap, and provides full access for cleaning and easy head removal

- Compact pedestal design that is fully mobile and features a manual height adjustable sewing line that ranges from 28 to 60 inches high.

- 24 VDC controls for safe, low voltage troubleshooting

- Dust tight NEMA 12 rated electrics

Options

- Synchronous Sewing Package with direct drive VFD

- Tagger Assist Front or Back

- Plain Sew Sensor Package for thread break and oil detection

- Rotary knife thread cutter Package

- Motor starter and contactor for conveyor

- Heavy Duty Dura Thread Clipper Package

- Fold Over Infeed Package (Not for multi-wall gusseted bags – for use on woven-poly pillow style bags only)

- Corrosion Resistant Package with NEMA 4 rated electrics

- Hazardous Location support features

- 575 VAC

Bag Types

Multi-wall paper, woven polypropylene, and jute bags, either pillow-style or gusseted.

Bag Thickness

Maximum 12 mils

Free Bag Top

Minimum 6 in (15.2 cm)

Standard Specs

Standard Specs

Dimensions

46″ (117 cm) L x 41″ (104 cm) D x 78″ (198 cm) H

Speed

Up to 55 linear feet per minute

Electric (NEMA 12)

230/380/460 VAC, 3 Ph, 50/60 Hz

Air

80-90 PSI, 15 SCFM